Our Excellent Products

Tengma tools delve into products with the spirit of craftsmanship pursuing quality, open up the market with the innovative power of keeping pace with the times, produce various specifications of thread rolling plates and thread rolling wheels, and carry out various standard customization according to customer needs.

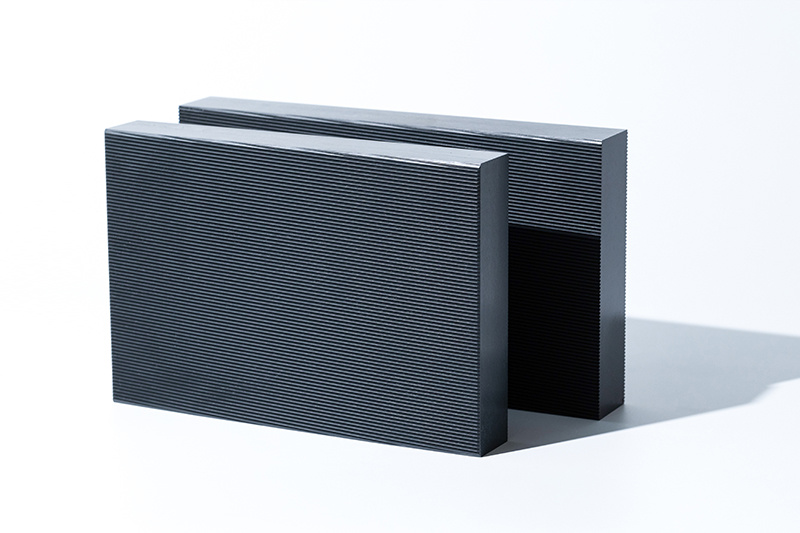

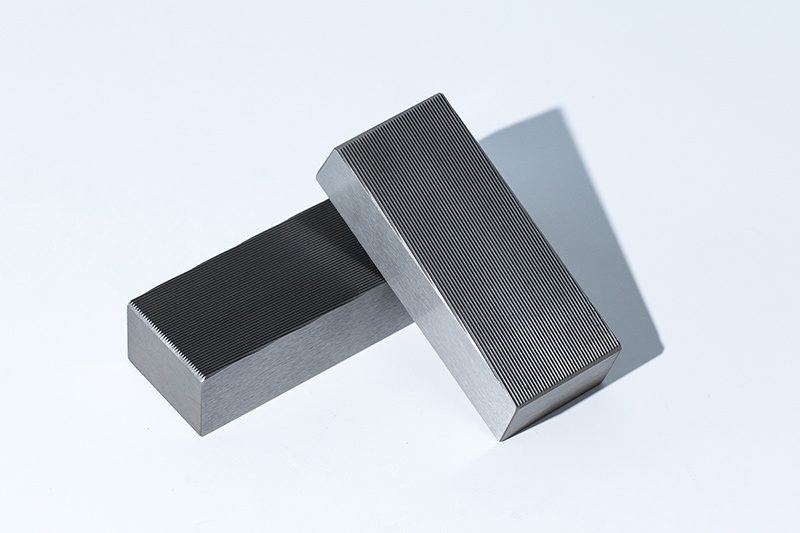

Washboard

Our company produces twisted wire boards with double-sided and single-sided, all made of DC53, D55, high-speed steel, and alloy tool steel, and using vacuum quenching heat treatment technology. They are suitable for processing ordinary bolts and high-strength bolts, with a wide variety and full specifications. Various special specifications of trapezoidal threads, serrated threads, screw module threads, 0.4-2.5 straight lines, mesh patterns, and various ring pattern rubbing plates.

Consulting

Consulting

Our company produces twisted wire boards with double-sided and single-sided, all made of DC53, D55, high-speed steel, and alloy tool steel, and using vacuum quenching heat treatment technology. They are suitable for processing ordinary bolts and high-strength bolts, with a wide variety and full specifications. Various special specifications of trapezoidal threads, serrated threads, screw module threads, 0.4-2.5 straight lines, mesh patterns, and various ring pattern rubbing plates.

Consulting

Consulting

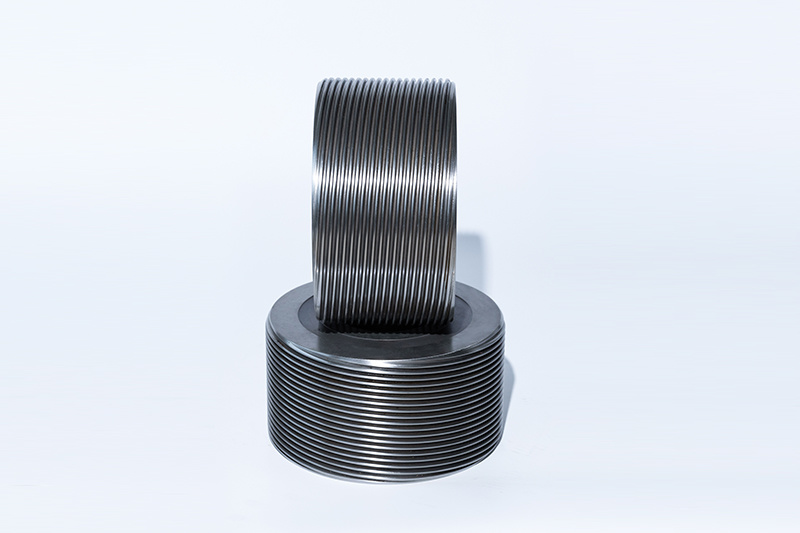

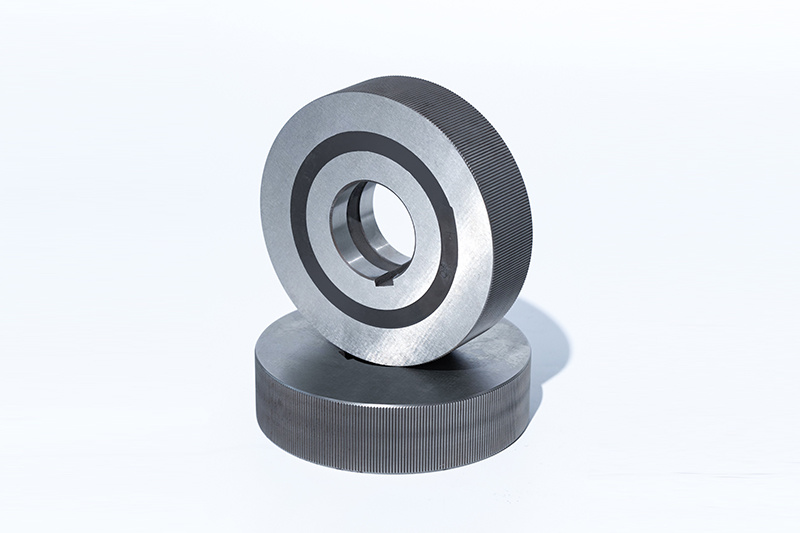

Thread Roller

The wire rolling wheels produced by our company have 130 holes, 120 holes, 110 holes, 100 holes, 85 holes, 75 holes, and 54 holes. They are made of alloy tool steel Cr12mo1v1 and use vacuum heat treatment technology. They can roll high-strength bolts of grades 12.9, 10.9, and 8.8, with high accuracy and long service life. They can also process various special threads (trapezoidal threads, worm module threads) according to user needs, as well as various types of string rolling wheels, tap rolling wheels, and three-axis rolling wheels.

Consulting

Consulting

The wire rolling wheels produced by our company have 130 holes, 120 holes, 110 holes, 100 holes, 85 holes, 75 holes, and 54 holes. They are made of alloy tool steel Cr12mo1v1 and use vacuum heat treatment technology. They can roll high-strength bolts of grades 12.9, 10.9, and 8.8, with high accuracy and long service life. They can also process various special threads (trapezoidal threads, worm module threads) according to user needs, as well as various types of string rolling wheels, tap rolling wheels, and three-axis rolling wheels.

Consulting

Consulting

Production

Production Capacity

Innovation-driven, efficient production

Tengma selection of alloy tool steel manufacturing, the use of vacuum heat treatment process, the production of washboard and rolling wheel, variety of high precision long life specifications.

Quality-oriented, precision is ruler

The quality comes from the careful control of every detail. Tuma's parameters such as pitch, tooth shape angle and tooth height are all precisely measured by universal microscope.

The first heart does not change, the quality does not forget

After more than 30 years of persistence and hardships, Tengma has never stopped and has successively obtained GB/T 19001-2016/ISO 9001:2015 quality system certification.

Cast the brand, create the future

With the spirit of excellence, casting every precision parts, we firmly believe that quality casts brand, ingenuity casts the future

30 Years Experience In TengMa

All Solutions

Tengma deep plowing alloy tool steel manufacturing 30 years

Standard Fastener

Washboard is a special tool for processing taps and bolts. Especially in the standard fastener industry, the most commonly used thread tool for processing screws and bolts is the washboard.

Metal products manufacturing

Used to produce threaded and spiral parts, such as bolts, nuts, guide rails, worms, gears and shafts. It can produce high-quality threads and gears, so it is widely used in this field.

Plastic products manufacturing

Filament rollers are also used in the production of plastic products such as pipes, wires and building materials. Plastic products made with thread rollers have a high degree of precision and a good surface finish.

Automobile manufacturing

The rolling wheel is also widely used in the field of automobile manufacturing, such as the manufacture of key components such as automobile threaded shafts and worms. This manufacturing method has high efficiency, low cost, and high precision of the manufactured product.

Mechanical manufacturing

Used in the manufacture of various mechanical parts, including gears, bearings, etc.

About Teng Ma

Learn About Tengma Tools

TengMa

Tengma Standard Parts Tools Co., Ltd. is located in Jiangyin, the hinterland of the Yangtze River Delta. Since its establishment in 1990, the company has studied its products with the spirit of craftsmen pursuing quality, opened up the market with the innovative power of keeping pace with the times, produced various specifications of thread rolling plates and thread rolling wheels, and customized various standards according to customer needs.

Tengma Tools was established in

OUR HONORS

After more than 30 years of persistence and baptism of wind and rain, Tengma has never stopped. It has not only won many honors, but also passed the GB/T 19001-2016/ISO 9001:2015 quality system certification.

Latest News

Get a Free Consultancy

Tengma Standard Parts and Tools Co., Ltd.

Tengma Standard Parts and Tools Co., Ltd.

Tengma tools specializing in the production of various specifications of the washboard, rolling wheel, and according to customer demand for a variety of standard customization.

202 Zhencheng Road, Jiangyin City, Jiangsu Province

Quick links

Copyright©2024 All Rights Reserved of Tengma Standard Parts and Tools Co., Ltd

2025-06-07

2025-06-07